Fully committed to a CSR approach since 2017, the Dômes Pharma Group has decided to integrate the Group’s CSR objectives into its strategic plan in 2021 and to opt for a CSR index that takes into account the profits or losses generated by the company’s social, environmental and economic activities in equal parts. One of the Group’s objectives for 2025 is to significantly improve its carbon footprint by achieving at least 2 life cycle improvements on 80% of the products manufactured at our production site by the end of 2025. This is the background to the packaging eco-design project.

A great deal of preparatory work was carried out in 2021 and 2022 to choose a system for calculating the carbon footprint, which enabled us to identify the top 10 products to be considered and the various ways of reducing CO2 emissions: saving energy on the production site, increasing waste recycling and replacing the packaging of finished products (boxes) with eco-responsible materials. At the end of 2022, the decision was taken to refocus the project on packaging, as the other areas for improvement had already been addressed by other working groups.

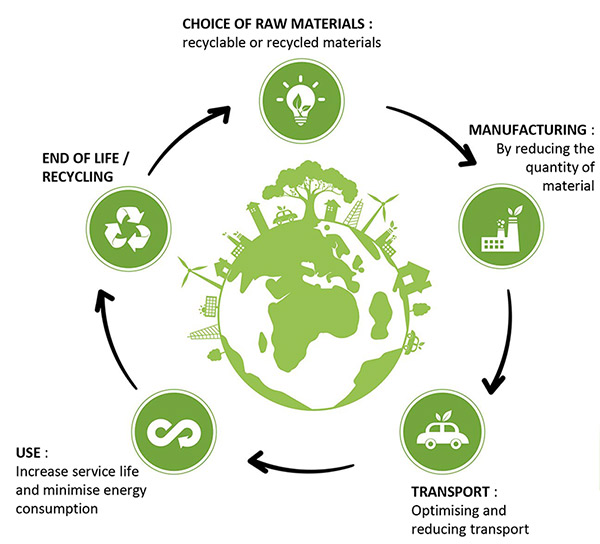

The aim of the project was therefore to develop or optimise packaging to improve the carbon impact of products. Improvements were envisaged in 3 areas:

Choice of raw materials: taking care not to lose the technical specifications of existing packaging.

Manufacturing: respect for the environment, forests, local populations, workers, etc.

Transport: reducing the transport impact of packaging

Various stages were necessary to assess the potential gains for each product: Identification of possible improvements for each product, selection of accessible solutions, test phase for each solution, validation and final choice, and finally feedback.

By definition, eco-design covers all the stages in the life cycle of a product or service:

In 2023, a group of 10 people from different functions took part in the project. A total of 10 products were studied, and various avenues of improvement investigated with a view to making changes that could reduce the carbon footprint of the targeted products by 15-20%. These changes included the use of recyclable materials, elimination or reduction in the weight of secondary packaging, elimination of paper leaflets, biosourcing of plastics, etc.

At the end of the tests, the results were as follows: 2 improvements were considered favourable, 2 improvable, 3 to be studied and 3 unfavourable.

7 product improvements have been validated and will be implemented on the 150 products selected. By the end of 2023, 61% of products had already benefited from these improvements. The target for the end of 2024 is to reach 80% of packaging that has benefited from at least 2 life-cycle improvements.

A second section concerns longer-term projects: